Hagen Engineering GmbH

Development Partner for the plastic industry

The Hagen Engineering GmbH was founded in 2002 as a spin-off out of the R&D department of the Dr. Reinold Hagen Stiftung. Since then we are established as a development partner which offers its customers engineering know-how and competence in plastics. Hagen Engineering GmbH takes charge of all production stages during development of new products – from realization of the idea in a process design to the production of prototypes, moulds and devices. The exclusive access to the technical centre of the Dr. Reinold Hagen Stiftung also enables us to offer material samples and small series for plastic products, especially in the field of blow moulding technology.

There is a close cooperation with the research department of the Dr. Reinold Hagen Stiftung. As a result, we are also able to take up and solve special questions that go beyond an ordinary service. Furthermore, we work closely with proven partners from the higher education sector and industry.

Our services includes:

- Product development and optimisation

- Process- and product-simulation

- Sampling of molds

- Trials during material developments

- Test series of new material or products (e.g. biobased raw material)

- Production of blow moulded articles (small scale series)

- Support with start of production

- Process development in collaboration

- Trainings

Processing equipment

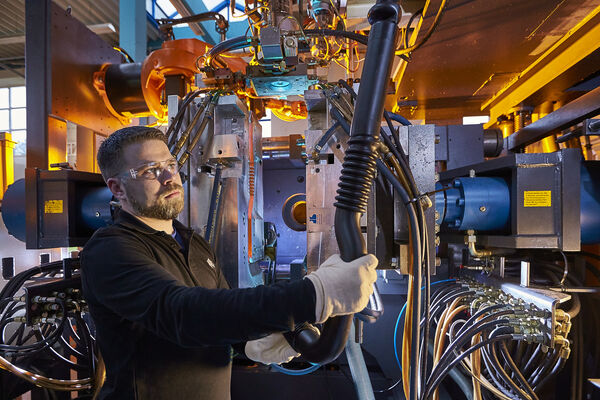

Extrusion blow moulding

ASPI 200

3D suction blow moulding and 2D conventional blow moulding processes

- accumulator head volume: 2,5 litre

- srew: 70 mm - 24 D

- clamping force: 200 kN

- tool dimensions: 1.400 mm x 800 mm x 500 mm (hight x depth x width)

- tool opening width: 500 mm - 1.400 mm

- tool opening stroke: max. 900 mm

KEB 4

conventional blow moulding with continous extrusion or accumulator head operation

- srew: 60 mm - 20D

- article size: 0,5- 5 litre

- clamping force: 100 kN

- tool dimensions: 470mm x 370mm x 270 mm (height x depth x width)

- tool opening width: 270 mm - 520 mm

- tool opening stroke: max. 250 mm

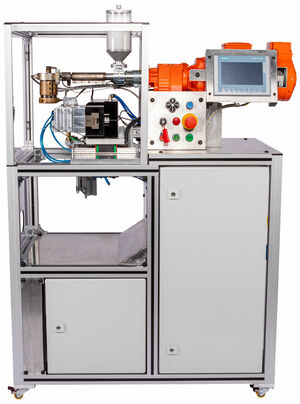

Blow moulding machine MiniBlow

Plastic hollow bodies with an article volume of approx. 80 ml can be produced on the machine.

- Installation space L: 1000mm, W: 600mm, H: 1500mm

- Weight of about 250kg

- Voltage: 230V

- Temperature range up to approx. 280°C

- Three-zone screw HSK25 D 16mm

- Screw for processing polyolefin granules

- Mass throughput approx. 2.5 kg/h; continuous extrusion

- Compressed air connection: 5-8 bar

Extrusion

Single-screw Extruder RH-78

- for extrusion- and material tests

- srew 35 mm - 25 D

Injection molding machine

- Arburg Allrounder 320 C

- Maximum injection pressure 2000 bar

- Screw diameter 30mm

- Locking force 500KN

Other equipment

- Thermoforming machine

- 5 side milling centre DMU 70

- CNC 3 milling axes machines

- Conventional Milling / turning machines

- Surface grinding machine